In this article, we will introduce how MYIR's Xilinx Zynq-7000 based Z-turn Board V2 used in agricultural production recognition systems.

The use of agricultural harvesting robots has progressively emerged as a new trend in intelligent agriculture as a result of advancements in agricultural production methods and vision technology. Automatic detection and identification of crops through machine vision technology has become one of the key technologies of harvesting robot design, which determines the effectiveness of the robots' harvesting and the economic viability of farms. The automatic picking robot using a single chip computer is currently the most popular picking robot on the market. The identification approach based on a large number of picture data training through the formation of neural networks, however, has become an essential requirement for the development of a new generation of intelligent agriculture due to the rapid development of artificial intelligence.

How to choose the CPU chip for upgrading agricultural production robots? FPGA real-time high-speed acquisition function, coupled with ARM high-performance processing system, is bound to be the best solution for the robot to build automatic identification picking system. Xilinx' Zynq-7000 ARM+FPGA SoC is a good choice, it can not only complete machine vision algorithms, but also implement robot control programs. In addition, the unique parallel processing capability of FPGA can identify and pick multiple targets at the same time, improving the picking efficiency; During this period, we can sort the fruit by optimizing the algorithm and training the image data.

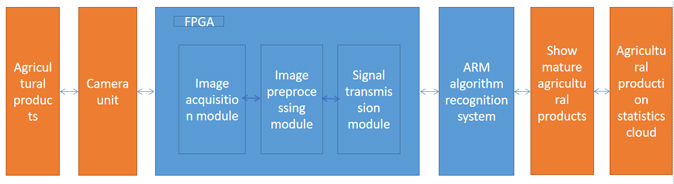

The workflow of the agricultural product identification system can be divided into the following steps:

(1) The camera collects images and sends image information to FPGA through a serial port to pre-process the image data.

(2) Call the recognition algorithm package of ZYNQ chip to identify the type, maturity, size and other relevant information of agricultural products.

(3) Display the corresponding agricultural product information on the touch screen and cloud through the network and multimedia interface, monitor the picture in real time and record the picked information.

(4) Under the coordination of FPGA and software, the coordinated information of fruit in the image is calculated, and the motor operating arm is controlled to pick the mature fruit.

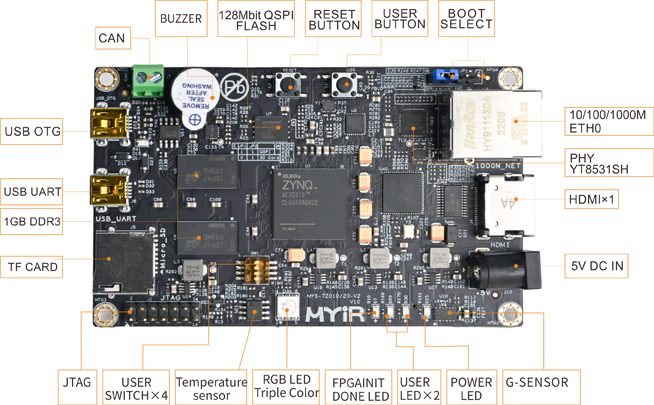

With the increasing demand for agricultural upgrading hardware, MYIR’s Z-turn Board V2 single board computers are used for the applications. The board is based on Xilinx Zynq 7Z010/20 SoC, which is designed for large-capacity storage to support long-term data storage of the system. Together with the extension board Z-turn IO Cape, it has provided camera interface, HDMI display interface and LCD interface to allow connecting with high-definition touch screens to display various data information, and realize local monitoring and real-time management of crops. With Gigabit Ethernet, CAN, PMOD, rich I/O and other data communication interfaces, it can easily meet various functional requirements in various scenarios. Moreover, the board supports PYNQ design platform. Designers can quickly build a more powerful embedded system by using Python language and libraries and the advantages of integrating programmable logic and microprocessors in Zynq.

The features of the Z-turn Board V2 are as following:

SOC: Xilinx Zynq-7010/20 high-performance dual-core ARM Cortex-A9 processing system (PS),

FPGA architecture: programmable logic unit XC7Z010 (28K, about 430,000 logic gates), XC7Z020 (85K, about 1.3 million logic gates)

Memory: 1GB DDR3 SDRAM (512MB * 2)

Storage: QSPI default 16MB, TF CARD slot (support external startup)

Network: 1 x Gigabit Ethernet

Video: HDMI interface

USB:1 x Mini USB2.0 OTG, 1 x USB-UART debug interface

CAN: 1 x CAN

JTAG: 1-channel PS/PL multiplexing JTAG interface (for programming, debugging and downloading)

User IO: Brought out via two 1.27mm pitch 80-pin SMT female connectors

- 90/106 user I/O (7010/7020)

- Configurable as up to 39 LVDS pairs I/O

Power supply: USB power supply or DC 5V/2A

Z-turn Board V2 (Top-view)

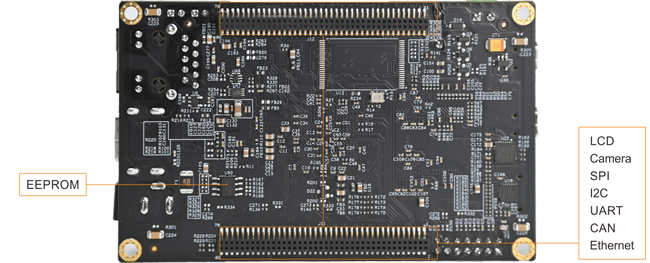

Z-turn Board V2 (Bottom-view)

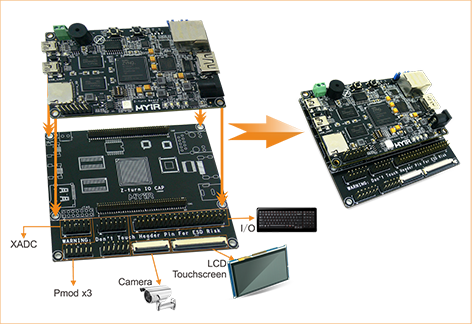

To enhance the diversity of development, MYIR has designed a dedicated Z-turn IO Cape for the Z-turn Board V2, which extends the common IO, ADC, LCD, camera interfaces, and other features of the Z-turn Board. which can be used together with more peripheral modules. It greatly expands the development scenario.

Z-turn Board V2 Mounted on Z-turn IO Cape

|