In recent years, with the development of the field of automatic control, the technology of camera lenses and visual recognition algorithms have become increasingly perfect. Based on this foundation, unmanned aerial vehicle (UAV) visual tracking technology has become a hot research field. What is UAV visual tracking technology? Firstly, the UAV collects video through a camera, stores the collected information, and identifies the set tracking target through algorithms to perform preset tasks. At present, UAV visual tracking technology has been widely used in fields such as agricultural production, military research, logistics and transportation.

Application of UAV in Agricultural Production

In the field of agricultural production, unmanned aerial vehicle visual tracking systems are used to identify the growth status of crops, for automated agricultural management such as high-altitude irrigation and pest control; In the civilian field, UAVs usually use visual tracking systems to recognize human gestures, allowing users to control the lifting and swinging of UAVs through gestures; In the field of biological research, this technology is mainly used to track and record the living habits of endangered wild animals and maintain ecosystem balance.

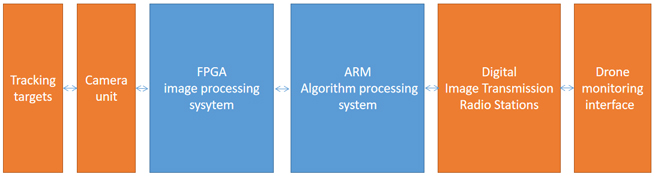

How is the UAV tracking system composed? Firstly, the UAV collects real-time image data through a high-definition camera module. The system converts the image information into digital information through a signal detection module and an image preprocessing module. Then, the data is sampled and quantified through a data acquisition and processing module, and each image parameter is analyzed and filtered; Compare the analysis results with the set tracking target for image recognition and tracking; The tracked image information can be transmitted to mobile phones and computers for real-time display through the network.

UAV Visual Tracking Flowchart

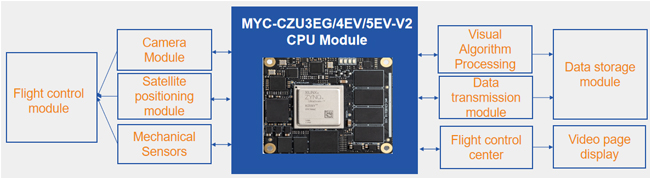

The unmanned aerial vehicle visual tracking system designed based on MYIR’s MYC-CZU4EV/5EV-V2 CPU Module can be divided into three parts: image signal acquisition, data processing, and information display; Image acquisition mainly collects image information through the camera, and then the FPGA chip high-speed collects and transmits the image information to the data processing unit. The data processing unit consists of VCU and MCU, which is responsible for annotating the collected image data with the set tracking target through algorithms; The information display part synchronizes the information to the drone control platform and APP through wireless transmission system, achieving real-time video transmission and mastering remote positioning and tracking functions.

Visual Tracking System based on MYC-CZU3EG/4EV/5EV-V2 CPU Module

The MYC-CZU3EG/4EV/5EV-V2 CPU Module is equipped with a fully functional high specification Zynq UltraScale+MPSoC chip, which integrates APU ARM Cortex on the PS side of the chip ™- A53 processor, RPU Cortex-R5 processor, Arm Mali-400 MP2 (GPU) with frequencies up to 667MHz. It should be noted that the 4EV/5EV chip has an additional video codec unit (VCU) compared to the 3EG chip, supporting H.264/H.265 encoding and decoding. The chip is equipped with internal memory, external memory interface (DDR), and peripheral interface. These peripheral interfaces mainly include USB bus interface, Ethernet interface, SD/eMMC interface, I2C bus interface, CAN bus interface, UART interface, GPIO, etc. High speed interfaces such as PCIE, SATA, and Display Port.

MYC-CZU3EG/4EV/5EV-V2 CPU Module (Top-view)

MYC-CZU3EG/4EV/5EV-V2 CPU Module (Bottom-view)

Features of MYC-CZU3EG/4EV/5EV-V2 CPU Module

Mechanical Parameters

-

Dimensions: 60.00 mm x 52.00 mm

-

PCB Layers: 12-layer design

-

Power supply: 3.3V

-

Working temp.: 0~70 Celsius (commercial grade, MYC-CZU3EG-V2), -40~85 Celsius (industrial grade, MYC-CZU4EV/5EV-V2)

MPSoC

-

Xilinx Zynq UltraScale+ XCZU3EG-1SFVC784 / XCZU4EV-1SFVC784 / XCZU5EV-2SFVC784 MPSoC

- 1.2GHz 64 bit Quad-core ARM® Cortex™-A53

- 600MHz Dual-core ARM® Cortex™-R5 processor

- ARM Mali™-400MP2 Graphics Processor

- 16nm FinFET+ FPGA fabric

Memory

-

4GB DDR4 SDRAM (64bit, 2400MHz)

-

4GB eMMC Flash

-

128MB QSPI Flash

Peripherals and Signals Routed to Pins

-

Gigabit Ethernet PHY

-

USB PHY

-

Power Module

-

Clock Generator

-

Watchdog

-

Four LEDs

- One yellow LED for ERROR_STATUS indicator (indicate a secure lockdown state)

- One yellow LED for ERROR_OUT indicator (Asserted for accidental power loss, hardware error)

- One green LED for PS_Done indicator (indicate the pl configuration is done)

- One green LED for PS_INIT indicator (indicate the ps is initialized after a power-on reset)

-

Two Samtec 0.5mm pitch 160-pin Razor Beam High-Speed headers bring out

- 4 PS GTR transceivers along with 2 GTR reference clock inputs

- PS JTAG interface, USB 2.0 interface, Gigabit Ethernet interface and etc.

- 4 PL GTH transceivers along with 1 GTH reference clock input (only for Zynq UltraScale+ EV Devices)

- 156 user PL I/O pins

OS Support

|